Lift tables, also called scissor lift tables, are extremely helpful in an industrial setting. These tables can adjust in height to help with loading pallets and other manual tasks. The fact that they can be adjusted helps cut down on the number of repetitive stress injuries that workers could sustain.

Using a lift table can also drastically cut down on the amount of time it takes to load and unload product coming into/out of your warehouse. There are a couple of different kinds to choose from based on the needs of your facility.

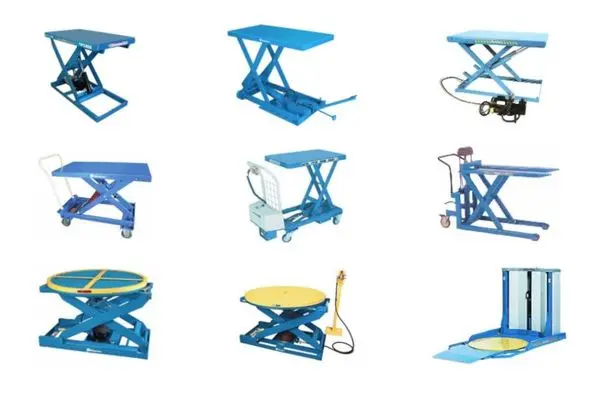

THE DIFFERENT TYPES OF LIFT TABLES

SCISSOR LIFT TABLES

MOBILE SCISSOR LIFT TABLES

PALLET POSITIONER LIFT TABLES

HOW TO DETERMINE THE TYPE OF LIFT TABLE YOU NEED

To figure out what kind of lift table you need, there are a few questions you need to ask yourself before you get started. Once you have the answer to these, you can then pick which table is best for your facility.

- How big of a table do I need?

- How much do the pallets weigh that will be sitting on this table?

- Do we need the ability to move our tables around?

- Does the height of the table need to be adjustable?

- Do we need the ability to rotate the table?

- Does the table need to be compatible with pallet trucks?

- How do you want the table to be operated?

Once you know these things, you will know if you need the standard, mobile, or pallet positioner style of table. Other factors to consider are making sure you buy a table that won’t be operating outside of its task safety limits and any safety features you will need your table to come equipped with.

BENEFITS OF USING LIFT TABLES IN YOUR FACILITY

The main reason to introduce lift tables into your facility will be financial. Lift tables will help your workers improve their productivity and this improvement will obviously help your bottom line. Studies have shown that using lift tables has improved worker productivity by as much as 40% in some facilities. That is an enormous payroll saving for any company.

Another place your business will see a large financial payoff is in workplace safety and the reduction of repetitive stress injuries. Loading and unloading product off of a lift table is repetitive work. A person will be lifting and turning dozens of times during the process. Over time, that process will cause repetitive stress injuries. Using a type of lift table dramatically cuts down on that kind of injury.

Lift tables help make your work area more ergonomically friendly and will reduce the amount of twisting involved. Reducing this type of motion will, in turn, reduce the number of workers with repetitive injuries. RSI injuries are expensive to treat. Your company does not want to assume that liability if you can avoid it.

LET DACO HELP YOU CHOOSE THE IDEAL LIFT TABLE FOR YOUR WORKPLACE

Not every lift table is created equal. Let DACO help you figure out the best table for your business. Our sales team knows the right questions to ask, so you get the right table for your needs. Contact us today to learn about our selection and inventory. Don’t forget to follow us on Facebook to keep up with the latest company news.