DRIVE-IN & DRIVE-THRU RACKING

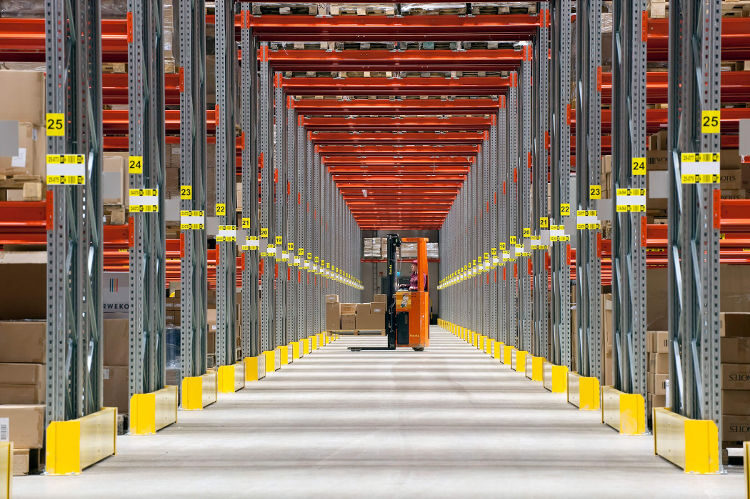

Ideal for storing large volumes of similar products, this system boosts storage efficiency by eliminating wasted aisle space.

HIGH DENSITY STORAGE

When it comes to high-density storage solutions, Drive-In and Drive-Thru Pallet Racking Systems offer efficient and effective options. These storage systems consist of uprights and support rails. The rails in this static system run through the depth of the racks. Pallets can be placed conveniently on the support rails with the help of a forklift. Both systems are typically designed to store from 2 to 10 pallets deep per pallet position.

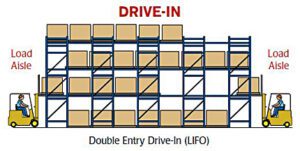

DRIVE-IN PALLET RACK

Drive-In pallet racking systems have a single entry/exit point. The pallets are loaded and retrieved from the same side making the last pallet loaded the first to be retrieved. The forklifts load a product onto the support rails by entering and retrieving while backing out of the rack. This type of pallet rack is called a last in, first out inventory system, otherwise known as LIFO. This racking system is perfect for products that are not date sensitive.

The defining feature that separates a drive-in pallet rack system from a drive-thru one. is the single opening for the forklift for loading as well as unloading. Both drive-in and drive-thru pallet racks offer excellent storage space, however, drive-in racks are often closed at one end by a wall or other installation. The forklift operators must drive into the racking system from one side and remove the pallets from the same entry point.

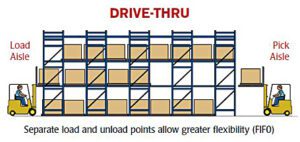

DRIVE-THRU PALLET RACK

Drive-thru pallet racking systems have a separate entry/exit point. The rack operators can enter the pallet racks to load the pallets from one end and unload the product from the other end. Additionally, both points can be used for loading and retrieval.

Drive-Thru pallet rack systems differ from drive-in systems as they use a first-in-first-out inventory retrieval system, also known as FIFO. The first pallet loaded on the rail system is conveniently the first pallet to be removed from the other end. This rotation of product through FIFO method makes drive-thru pallet rack perfect for date-sensitive pallets. Fast moving items or perishables can efficiently be stored in drive-thru rack. from the same entry point.

EFFICIENT STORAGE

Both pallet racking systems provide maximum cubed space utilization. The floor-to-ceiling storage optimizes vertical space and significant depth of the racks reduces the need for traditional aisles. The greater density of storage in both these systems allows seven times more storage room than floor stacking and three times more than the traditional pallet racks. Both systems are ideal for freezer or cold storage applications as well

Both drive-in and drive-thru pallet rack is usually available in both structural and roll formed steel and are easy to set up and install. The simple support arms strongly hold the support-rails in place. The adaptability of the structure allows it to be attached to standard pallet rack, as well as special structural designs. The racks can be tied to the overhead structure, or more efficient overhead bracing can be used to give the racks firmness and rigidity.

These systems depend heavily on forklifts for the movement of products. This fact increases the potential for pallet rack damage. It is imperative for the forklift drivers to meticulously follow pallet rack safety rules and report any damage to the rack systems.

Both drive-in and drive-thru pallet racking systems offer comprehensive and cost-effective storage options for large quantities of similar products. They offer incomparable storage capacity at very affordable costs.

FEATURES & BENEFITS OF DRIVE-IN & DRIVE-THRU PALLET RACKING

- High density, low selectively pallet rack system.

- Depth of the pallet rack system reduces the need for aisles and increases space utilization.

- Makes best use of the available surface and height space than any other system.

- Allows for load flexibility in regards to both weight and volume.

- Specifically designed for uniform pallet loads.

- Easy to assemble.

- Cost effective.

DRIVE-IN & DRIVE-THRU PALLET RACKING IS IDEAL FOR STORING:

- Drive-in Pallet Rack – slow moving, non-perishable products.

- Drive-Thru Pallet Rack – fast moving, perishable products.

- Large amounts of the same SKUs.

- Storage freezers.

- Seasonal warehouses.

LET US DESIGN THE PERFECT PALLET RACK SYSTEM FOR YOU

We look forward to partnering with you to design and install the ideal pallet racking system to meet your long term storage needs.

CONTACT US TODAY