Can we help you find what you need?

Talk with our team or send us a message.

- Live Chat (Lower Right Corner)

- 📞 Call Now 877-764-0453

- ✉️ Send a Message

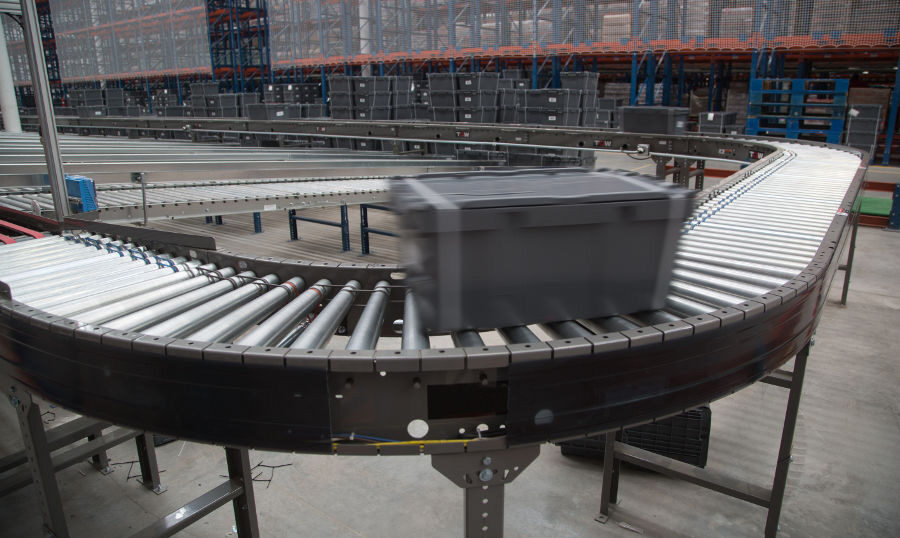

Conveyor Systems are used to safely and efficiently transport materials from one location to another within your facility. The materials travel down the conveyor line on either rollers or belts, loading or unloading materials in various areas, until they reach their final destination.

These conveyor systems can be either gravity or electric powered, and help to reduce manual labor and increase productivity and process efficiencies within your facility.

Gravity conveyor is also known as a non-powered conveyor as it uses the force of gravity as its power source. It is the simplest style of conveyor and is commonly used in packaging and pallet handling, assembly, kitting, and truck unloading areas. They consist of a series of evenly spaced metal rollers that facilitate the movement of materials from point A to point B.

The conveyor is usually constructed at a slight incline and uses the force of gravity or manual force to move materials down the conveyor line. Gravity conveyor systems are a popular choice due to their simplicity and affordability.

A powered conveyor is motorized and driven by either electric or pneumatic power systems. They are commonly used to transport pallets and packages from one point to another, quickly and safely. There are several types to choose from and each operates a little differently.

Our systems experts can help you analyze your current workflow and determine if, and which conveyor system can help increase your productivity and decrease your labor costs. We look forward to discussing your challenges, and coming up with a solution.

CONTACT US TODAY