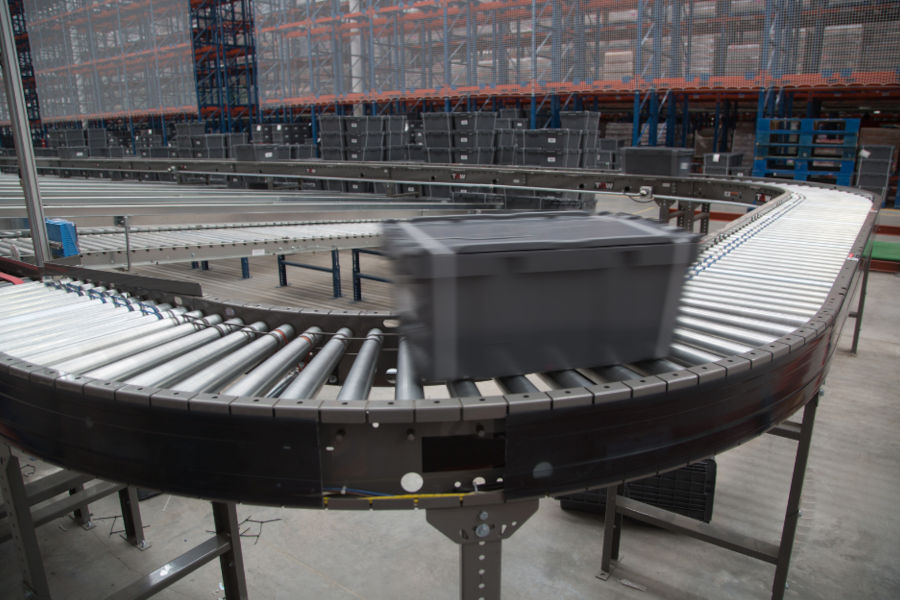

Unloading trucks means moving a lot of product from the truck to the dock or warehouse. Gravity roller conveyor systems provide a great material handling solution for offloading trucks. These versatile solutions have many different benefits and many industries are saving time, as well as money when choosing gravity conveyors. For facilities that need to move high volumes of goods, they can speed up the loading and unloading processes drastically.

ECONOMICAL ADVANTAGE

Gravity roller conveyor systems use gravity to move merchandise from trucks to your dock or warehouse. With no motor involved, the cost is very minimal. Motor-powered engines can consume electricity or usage of batteries; either of these resources increases the cost of operation. Controlled loading and unloading processes mean less risk of damaged goods or equipment.

LOW MAINTENANCE

You can save operational costs by using a gravity-operated conveyor and there also little to no maintenance or repair needed in an ongoing basis. With no motor to break down, costly downtime is avoidable, and there are no costs for hiring outside contractors or engineers for repairs. Roller wheels will need to be kept free from debris or buildup.

VERSATILE APPLICATIONS

Gravity conveyors are versatile and useful in many industrial environments beyond truck offloading. They move goods quickly and cheaply in distribution centers, warehouses, shipping and receiving settings, or order-picking businesses. After offloading trucks, they can be moved and used for other applications. The configuration can be changed so the conveyor can help manage everything from food packaging to furniture or medical supplies to vehicle parts.

They can be mobile and adapted to various environments, or they can be stationary and installed permanently. Gravity conveyors can also be used along with other product handling systems to improve efficiency.

SAFETY FIRST

There is no debate on workplaces needing to be safe. Gravity conveyors can help keep areas safe by reducing congestion. Conveyor systems are equipped with foot breaks to ensure they do not move while the product is being moved. Heavy-duty swivel casters provide mobility as well as exceptional strength.

TIME AND SPACE-EFFICIENT

One of the most common uses for gravity conveyors is loading and unloading trucks. This is primarily due to being able to increase process efficiency. Since there are fewer logistics needed, the loading and unloading process runs smoother. Each conveyor-equipped dock can handle higher volumes which transpires into faster loading and unloading times. Trailer turnaround time is quicker, so there is less outside space needed at any given time and less overflow stock to deal with.

CHOOSE A GRAVITY CONVEYOR

If you are looking for a faster, more economical, and more practical way to offload trucks, a gravity roller conveyor system is the way to go. There are many benefits, such as not consuming power and the lack of motorized parts. They are one of the most economical solutions in warehousing today. Gravity-operated conveyors are versatile and easy to use.