It’s no secret that manufacturing, warehousing, and distribution centers can be environments of mass chaos. It’s important to keep these areas of your business working smoothly, and organization is key. Manual systems don’t allow you the type of control you need over your processes, equipment, and time. However, a pick module system will. DACO can help you design an automated system that works well for your facility. It’s time to take charge of your warehouse operations and upgrade to a system that enhances productivity, space, and organization.

WHAT ARE PICK MODULE SYSTEMS?

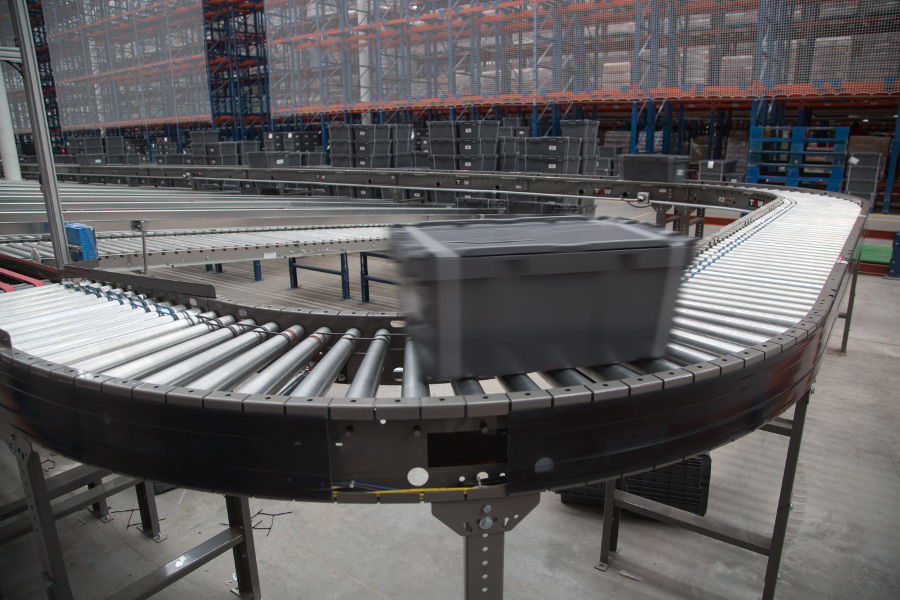

Pick Module Systems are high density storage systems, that can consist of and combine, many different storage and handling solutions, including pallet racking, conveyor, ASRS systems, AGV’s and mezzanines. They are intertwined inside multi-level work platforms, allowing product to move more efficiently through a multilevel warehouse or distribution center.

A PICK MODULE SYSTEM INCREASES PRODUCTIVITY

The most important aspect of your business is productivity. You can’t make money when your staff is unable to efficiently put out products. Having an outdated manual system in place is truly a thing of the past. Pick module systems are becoming more popular as the years go by and pretty soon, all warehouses will be using them.

Pick module systems help you meet your business goals and deadlines on time by ensuring increased productivity, among other benefits:

- Labor and production costs are decreased

- Space is more efficiently utilized

- Improved scheduling

- Creates a smooth and continuous flow of materials and information

- Better communication between suppliers and clients

- Decreased delays between departments and operations

- Decreased incidence of product damage

- System changes become more adaptable

- Maximum return on investment

ECONOMIC DESIGN THAT MEETS THE DEMANDS OF YOUR BUSINESS

Did you know these pick module systems can be customized to create the most efficient high-volume case picking and small parts distribution system available? These types of systems are designed to create a dynamic, interconnected system within your warehouse. From the pallet racking stage to the shipping dock, a pick module system keeps productivity running without a hitch.

Pick module systems are custom designed with your business in mind:

- Immense attention to detail during system design

- Push-back and flow racks can easily be incorporated

- Single, double, triple, and level systems available

- Supported full or split case picking

- Vertical space is maximized within your distribution center

- Improves efficiency across many applications

- Pick module systems can be designed to grow with your business

Implementing a pick module system into your warehouse is a wise investment because it literally pays for itself. When productivity increases, so will your profits.

IMPROVE EFFICIENCY WITH AN DACO PICK MODULE SYSTEM

Our staff looks forward to chatting with you about your new pick module system. Each system is custom designed to meet the individual needs of your business. When it comes to module pick systems, DACO is the company to trust. We have decades of experience on our side and hope to share our knowledge with you.

Don’t forget to like and follow us on Facebook!

WASHINGTON

Phone: 253-395-8500

Fax: 253-395-8585

OREGON

Phone: 503-722-4390

Fax: 503-557-1184