VL Series Vertical Hydraulic Loading Dock Levelers

- Model: VL Series

NON STOCK ITEM - Ships from Mississauga, ON, Canada L5T N6

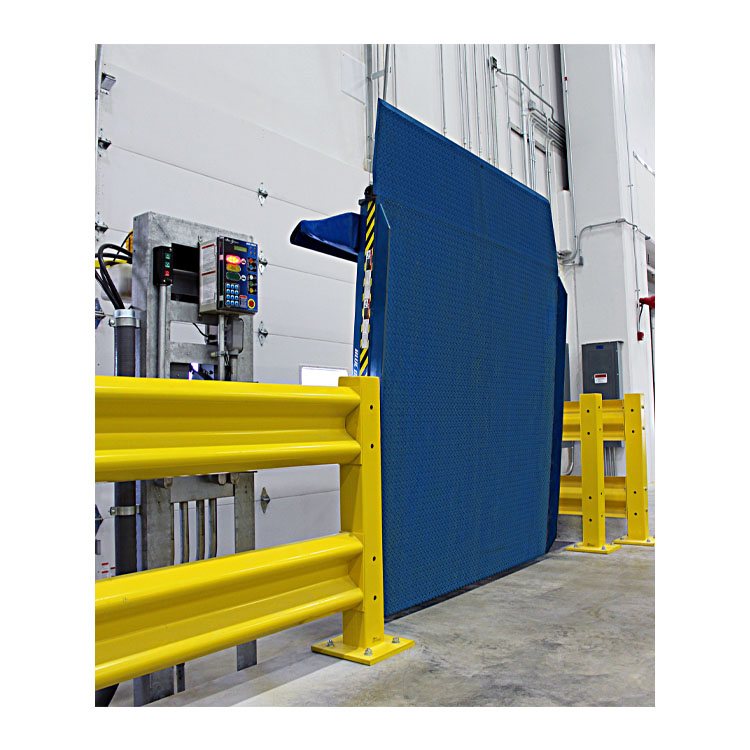

VL Series Vertical Loading Dock Levelers are stored or parked in a vertical position. When servicing a trailer, it is lowered at a controlled rate until it rests on the bed of the trailer. After the loading/unloading operations are finished, the operator activates the raise button to bring the leveler back to the vertical (stored) position. A dual storage locking system comprised of an electro / hydraulic and mechanical lock should be incorporated for additional safety when stored. Also, an emergency stop button should be provided to halt the lowering of the deck if necessary.

Vertical storing loading dock levelers are commonly used for food storage or processing facilities. Open pit or ledge installation makes it easy to keep the dock area clean and maintain standards. The overhead doors can be closed and secured down to the concrete surface resulting in better climate control, security, and reduced access by vermin and insects.

Efficiency can also be increased with these levelers. Since they are set back from the dock face, the trailer can be positioned and then the hinged trailer doors opened. This eliminates the need to maneuver, get out and open the doors, and position at the dock.

When the overhead door is closed and the leveler is in the vertical position, it acts as a visual barrier. Consequently, the overhead doors are protected against damage from loading vehicle impacts.

Perfect for LEED certified projects. This vertical loading dock leveler is ideal for applications that require climate control or high sanitary levels by assisting to control internal temperature, reducing the chance of door damage, and decreasing the amount of debris that enters at the doorway. When the vehicle backs into the loading dock bay, a complete seal is formed between the trailer and inside of the facility, before the doors are opened, which decreases the chance for contamination.

Feature & Benefits of VL Series Vertical Loading Dock Levelers:

- 30,000 to 60,000 lb. rated capacities.

- IntelliTilt™ technology uses a precision-based inclinometer to provide accurate and safe and dock positioning.

- SmartFloat™ enables the deck to seamlessly match trailer movement during loading and unloading processes.

- The unique EasyClean™ deck hinge configuration has no dirt entrapment points.

- SoftPark™ protective cushioning shields the deck cylinder, preserving equipment integrity.

- Controlled by the Blue Genius™ Gold Series I Touch Control Panel.

- Continuous one-piece headboard system intensifies the strength of the deck’s front structure.

- 1HP motor is equipped with overload protection.

- Platform flexes up to 4" (102mm) under load, maintaining full-width contact between the lip and the truck bed.

- Inverted deck cylinder self-bleeds continually, reducing internal corrosion and increasing velocity fuse efficiency.

- Hydraulic velocity fuse limits free-fall of a loaded platform.

- Single lip hinge pin enables a stronger distributed load.

- 3" (76mm) run-off guards keep forklifts properly positioned.

-

VL Series Vertical Hydraulic Loading Dock Leveler Literature